Advanced Manufacturing Technology

What is Advanced Manufacturing Technology?

The Advanced Manufacturing Technology program prepares students for a rewarding and challenging career by providing them with entry-level training for the manufacturing industry. The machining industry utilizes precision tools and equipment to transform engineers’ and designers’ visions into finished products. The training in the Advanced Manufacturing Technology program focuses on the skills that are in demand in the local and national job market. These are the skills required by the high-tech modern manufacturing businesses such as aerospace, medical instrumentation, defense, and many more.

Students in the program learn the use of hand tools, manual machine tools, and Computer Numerical Control (CNC) machine tools to cut metals within .0001 of an inch. Curriculum topics include manual and CNC milling, manual and CNC turning, and precision grinding. As well as an extreme focus on precision Measurement. Students also learn interpretation of blueprint drawings to gain understanding of machining industry specifications. Training also includes precision inspection using sophisticated measuring equipment, a toolmaker’s microscope, and an optical comparator within the metrology lab, where quality assurance is emphasized.

Is it for You?

Students seeking to enter this program should enjoy working with machines, both computerized and manual. Most positions in this field require work as part of a team, so students should be willing and able to work in groups. Employees tend to start "at the bottom", but can advance to management or supervisory positions; work weeks are typically 40 hours year round.

It is important to note that the following skills are necessary for employment in this field:

Excellent mathematical ability.

Ability to work under strict guidelines and instructions.

Good eye and hand coordination.

Good eyesight (either naturally or with correction).

Program Objectives

| Level 1 Certifications: NIMS Measurement, Materials, and Safety, NIMS Turning Operations

POS TASKS:

|

Level 2 Certification: NIMS Drill Press Skills I, NIMS Manual Milling Skills I, NIMS Grinding Skills I CHS: MDES 207 (Machine Shop Theory and Practice) and MDRF 101 (Engineering Drawing)

POS TASKS:

Employability Skills Training | Level 3 Certifications: NIMS CNC Turning, NIMS CNC Milling CHS: UA 205 (Computer Numeric Control)

POS TASKS:

OPTION: Cooperative Education |

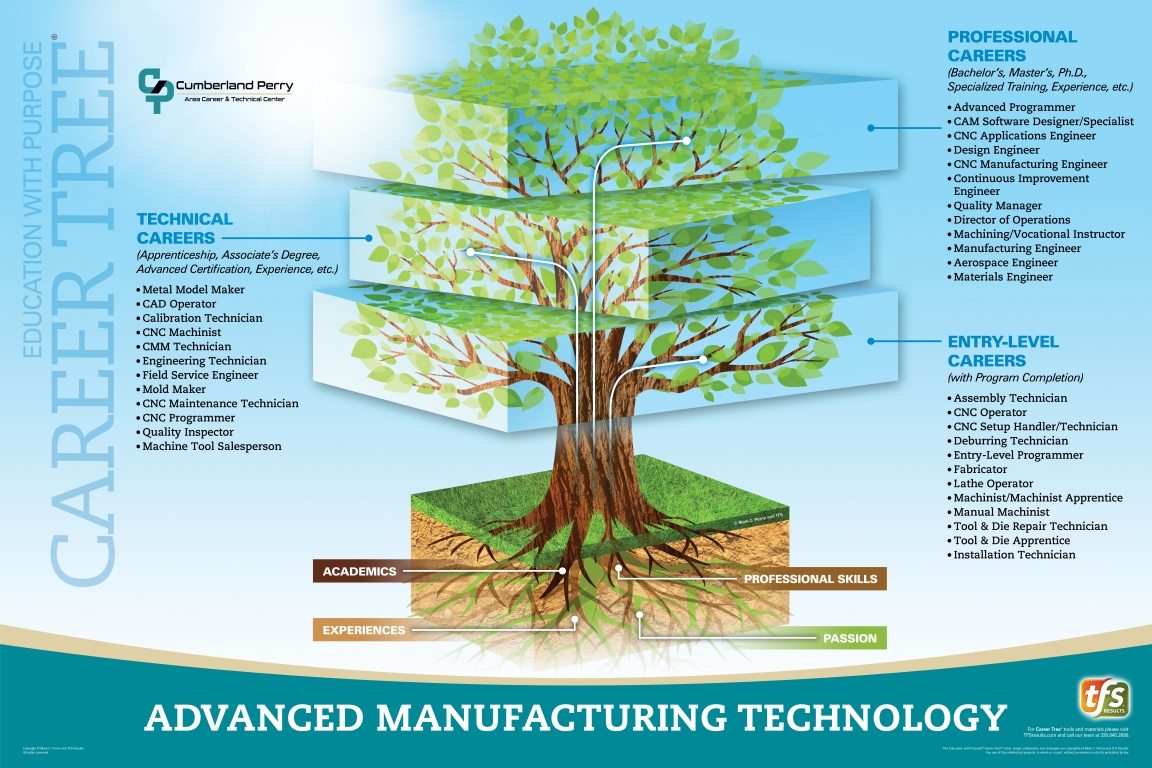

What Can You Do as a Graduate of Advanced Manufacturing Technology?

Potential Career Pathways

* Salaries listed are PA state averages taken from www.onetonline.com and are accurate as of 2020.

CNC Machine Tool Operators, Metal & Plastic ($42,260)

Machinists ($46,340)

Tool and Die Makers ($47,580)

Lathe & Turning Machine Tool Setters, Operators & Tenders, Metal & Plastic ($39,380)

Milling & Planing Machine Setters, Operators & Tenders, Metal & Plastic ($41,590)

CNC Machine Programmers ($58,550)

...and many more

Post-Secondary Studies

*Many employment options in this field require additional study.

Penn College: Machine Tool Technology, Automated Manufacturing Technology

Thaddeus Stevens: Machine Tool & Computer Aided Manufacturing